As an important component of plastic bags, the secret of vacuum packaging lies in the perfect combination of vacuum bags and vacuum sealing technology to create an anaerobic and sterile "hibernation chamber" for food ingredients. Proper use of vacuum packaging can not only extend the shelf life of food by 3-5 times, but also lock in nutrients and original flavors. So how should we standardize the use of packaging bags?

● Choosing the right vacuum bags is the first step to success

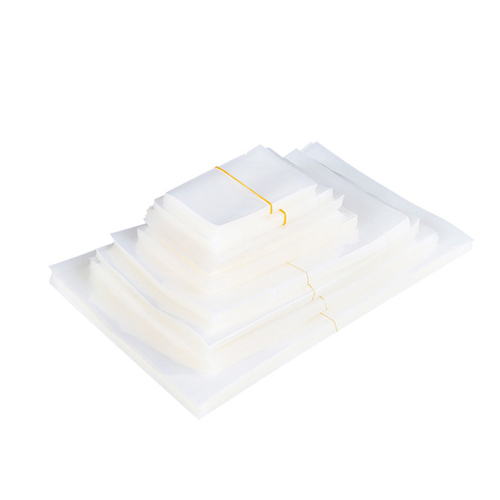

High quality vacuum bags should adopt a five layer co extrusion structure. Ordinary plastic bags lack a composite barrier layer, resulting in a daily oxygen permeability of up to 0.5cc/m ² after vacuum bags pumping, while professional vacuum bags have a permeability of less than 0.03cc/m ². Choose a vacuum bags with a three-dimensional indentation, whose corrugated sealing design can increase the contact area of the vacuum sealing and improve the vacuum bags sealing strength by 60% compared to ordinary smooth packaging bags. Remember to check whether the plastic bags is printed with the " food grade vacuum packaging " label, this is the first level of quality assurance.

● Details determine the success or failure of preservation

Before loading ingredients, use alcohol swabs to clean the inner wall of the vacuum bags to prevent vacuum sealing oil residue from affecting the vacuum sealing effect. Sharp ingredients such as bone in steak should be wrapped in a silicone protective cover before being placed in a packaging bags. Vacuum packaging pumping should follow the " vacuum sealing two-stage negative pressure method ". During heat sealing, the vacuum sealing temperature should be controlled at 180-200 ℃, and the vacuum sealing width should reach 8-10mm, which is equivalent to the width of an adult thumb. After completing the vacuum packaging, the plastic bags can be completely immersed in ice water. If no continuous bubbles emerge, it proves that the packaging bags is perfectly sealed.

● Environmental synergy doubles the effect

Fresh meat vacuum packaging should be prioritized for storage in a 0-4 ℃ refrigerated area, where the growth rate of microorganisms on plastic bags is reduced by 80%. If frozen storage is required, a low-temperature resistant vacuum bags must be used. Ordinary packaging bags will become brittle and crack at -18 ℃. When refrigerating, the vacuum bags should be placed flat to avoid packaging bags squeezing, and when freezing, it should be placed vertically to facilitate the circulation of cold air. Regularly check the vacuum sealing status. If the packaging bags expands by more than 20% of its original volume, it may indicate the presence of micropores in the plastic bags sealing layer, and immediate unpacking packaging bags and repackaging are required.

● Make the vacuum packaging machine last as good as new

Wipe the sealing strip of the plastic bags vacuum packaging machine with a damp cloth daily to prevent carbonization of food residue from affecting the vacuum sealing performance. Clean the plastic bags vacuum chamber of the packaging bags with a cotton swab dipped in alcohol every month to avoid oil accumulation and reduce negative pressure efficiency. Vacuum bags that have not been used for a long time should be sealed and stored away from light to prevent oxidation of the plastic bags aluminum foil layer and a decrease in barrier performance. Ordinary plastic bags should never be used for vacuum storage, as their oxygen permeability is more than 20 times that of professional plastic bags vacuum bags, which can cause food to spoil within 3-5 days.

About Us

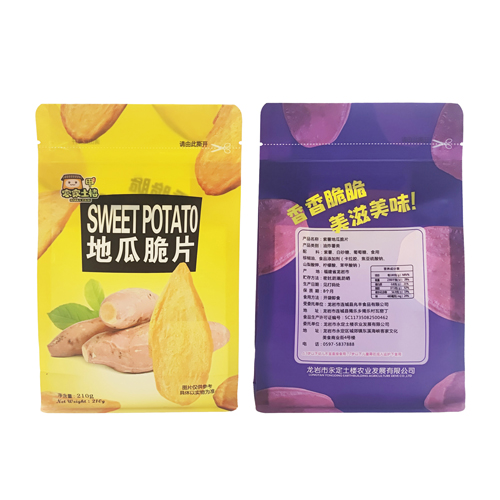

Fujin New Materials, After Several Years Of Development, Has Developed Into A Packaging Enterprise With A Certain Scale. Our Company Integrates R & D, Design, Printing, Bag Making, Testing And After-Sales Service Into A Comprehensive Printing Company. Our Company Is Specialized In Producing Vacuum Food Bag, Aluminum Foil Bag, Opp Bags, Pe Bags, Recyclable Coffee Bag, Kraft Paper Ziplock Bags, Snacks Packaging Pouches, Stand Up Ziplock Bags, Pet Food Bag, Etc.