Roast duck, as one of the representatives of traditional Chinese cuisine, has always been loved by a large number of consumers. In order to maintain the taste of roasted duck and extend its shelf life, vacuum packaging has become a common choice. However, vacuum packaging of roasted duck is not simply about placing the duck in a bag and extracting air, but requires attention to multiple aspects to ensure food safety and quality.

● Select qualified vacuum bags

○ Material: Vacuum bags should be made of materials that meet safety standards, such as food grade polyethylene (PE), polypropylene (PP), etc. These materials have the characteristics of non-toxic, odorless, and high transparency, making them suitable for food packaging.

○ Thickness: The thickness of the vacuum bag should be selected according to the size and weight of the roasted duck. Generally speaking, a thickness of 80-120 microns is more suitable. Being too thin can easily cause damage, while being too thick can affect the packaging effect.

○ Sealing: The sealing of the vacuum bag should be firm and flat to ensure that there is no air leakage after vacuum packaging. The sealing width should be 10-15 millimeters to ensure sealing strength.

● Key points of vacuum packaging operation

○ Check the vacuum bag: Before packaging, carefully inspect the vacuum bag for any damage, leaks, or other defects to ensure the packaging effect.

○ Add roasted duck: Place the pre processed roasted duck into a vacuum bag, being careful not to fold or squeeze it, so as not to affect the taste of the roasted duck.

○ Vacuuming: Start the vacuum packaging machine to extract the air inside the vacuum bag. The vacuuming time should be adjusted according to the size and weight of the roasted duck, generally controlled within 20-30 seconds.

○ Heat sealing: Immediately perform heat sealing after vacuuming is completed. The heat sealing temperature and time should be adjusted according to the material of the vacuum bag, with the principle of firm and smooth sealing.

○ Inspection: After the heat sealing is completed, check whether the vacuum bag has any air leakage, damage, or other phenomena. If there are any problems, adjust the equipment parameters or replace the vacuum bag in a timely manner.

● Storage and transportation

○ Storage: Vacuum packaged roasted duck should be stored in a cool, dry, and well ventilated place, away from direct sunlight. The storage temperature should be controlled between 0-4 ℃, and the relative humidity should be between 60% and 75%.

○ Transportation: During transportation, handle with care to avoid squeezing and collision. Try to use cold chain transportation to ensure the quality of roasted duck.

About Us

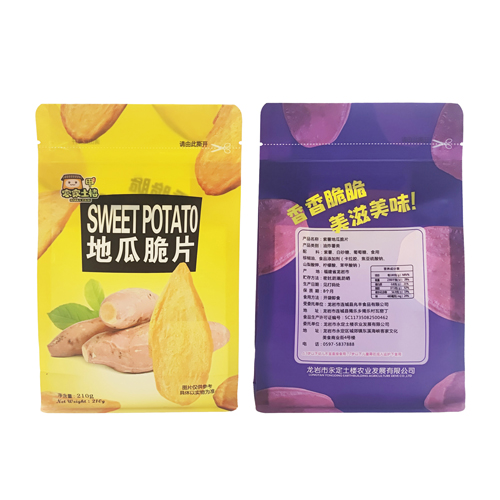

Fujin New Materials, After Several Years Of Development, Has Developed Into A Packaging Enterprise With A Certain Scale. Our Company Integrates R & D, Design, Printing, Bag Making, Testing And After-Sales Service Into A Comprehensive Printing Company. Our Company Is Specialized In Producing Vacuum Food Bag, Aluminum Foil Bag, Opp Bags, Pe Bags, Recyclable Coffee Bag, Kraft Paper Ziplock Bags, Snacks Packaging Pouches, Stand Up Ziplock Bags, Pet Food Bag, Etc.