In modern packaging technology, vacuum packaging bags are widely used in various fields such as food, medicine, electronic products, textiles, etc. due to their excellent preservation, oxidation resistance, corrosion resistance, and extended product shelf life. Facing the dazzling array of vacuum packaging bag products in the market, how to choose packaging bags that meet their own needs and have superior quality has become a focus of attention for many consumers and businesses.

● Understand the material of vacuum packaging bags

○ The materials of vacuum packaging bags mainly include the following:

◇ Food grade plastic film: such as PE (polyethylene), PA (nylon), PET (polyester), etc. This type of material is safe, non-toxic, and suitable for food packaging.

◇ Composite materials: Combining multiple materials together for better barrier properties. Such as PE+PA, PET+PE, etc.

◇ Nanomaterials: with excellent antibacterial and barrier properties, suitable for high-end food packaging.

○ When making a purchase, please pay attention to the following points:

◇ Material safety: Ensure that avoid the use of inferior materials.

◇ Barrier performance: Select materials with corresponding barrier properties based on the characteristics of the food. For perishable foods such as meat and seafood, composite materials with good barrier properties should be selected.

◇ Shelf life: Vacuum packaging bags made of different materials have different shelf lives. Generally speaking, vacuum packaging bags made of composite materials and nanomaterials have a longer shelf life.

● Pay attention to the size and thickness of vacuum packaging bags

○ Size: Choose the appropriate size according to actual needs. Vacuum packaging bags come in various sizes, such as width, length, thickness, etc. It is recommended to reserve a certain amount of space for packaging when making a purchase.

○ Thickness: The thickness of vacuum packaging bags directly affects their sealing performance and durability. Generally speaking, the thicker the thickness, the better the sealing performance and the longer the service life. But practical needs should also be considered to avoid excessive waste.

● Check the sealing performance of vacuum packaging bags

○ Sealing strip: Check whether the sealing strip of the vacuum packaging bag is flat and undamaged. The quality of the sealing strip is directly related to the sealing performance of the packaging bag.

○ Heat sealing strength: The higher the heat sealing strength, the better the sealing performance. When making a purchase, you can try tearing open the sealed part by hand to feel its strength.

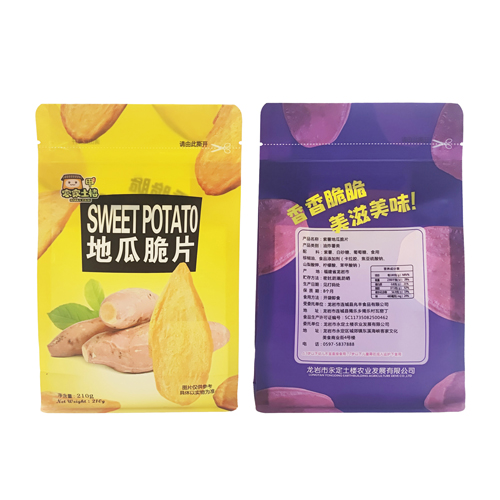

● Understand the printing quality of vacuum packaging bags

○ Printing clarity: Check whether the text and patterns on the vacuum packaging bag are clear and free of ghosting.

○ Color: The color should be bright, uniform, and without fading.

○ Ink safety: Ensure that the ink used in vacuum packaging bags meets food safety standards.

● Choose legitimate channels to purchase

○ Brand reputation: Choose a brand with high visibility and good reputation.

○ After sales service: Understand the manufacturer's after-sales service policy to ensure timely resolution of any issues encountered.

About Us

Fujin New Materials, After Several Years Of Development, Has Developed Into A Packaging Enterprise With A Certain Scale. Our Company Integrates R & D, Design, Printing, Bag Making, Testing And After-Sales Service Into A Comprehensive Printing Company. Our Company Is Specialized In Producing Vacuum Food Bag, Aluminum Foil Bag, Opp Bags, Pe Bags, Recyclable Coffee Bag, Kraft Paper Ziplock Bags, Snacks Packaging Pouches, Stand Up Ziplock Bags, Pet Food Bag, Etc.