As a popular snack, pistachios rely heavily on appropriate packaging choices for their quality and taste. The correct packaging material can not only effectively maintain the freshness and taste of pistachios, but also enhance the overall image of the product and the purchasing experience of consumers.

● Types of packaging bag materials for pistachios

○ Plastic material: Plastic packaging bags are currently the most common packaging material for pistachios in the market, with characteristics such as lightweight, waterproof, and good sealing performance. Plastic materials mainly include PE (polyethylene), PP (polypropylene), PET (polyethylene terephthalate), etc.

○ Paper material: Paper packaging bags are environmentally friendly, biodegradable, and have good texture, making them suitable for consumers who pursue green and high-quality products. Paper materials mainly include kraft paper, copperplate paper, etc.

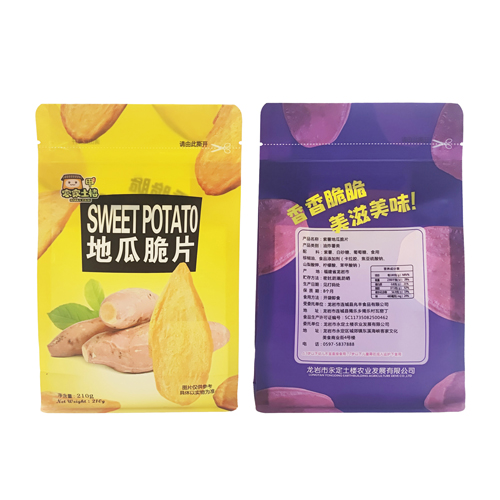

○ Composite material: Composite packaging bags are made by combining various materials such as plastic and paper together, providing better protection and aesthetics. Common composite materials include aluminum foil composite bags, plastic composite paper bags, etc.

● Key points for selecting materials for packaging bags of pistachios

○ Moisture resistance: Pistachios are prone to moisture, leading to a deterioration in taste. Therefore, when choosing packaging bags, attention should be paid to their moisture resistance. Plastic and composite packaging bags have good moisture resistance, among which aluminum foil composite bags have the best moisture resistance.

○ Anti oxidation performance: Pistachios contain a high amount of unsaturated fatty acids, which are prone to oxidation and deterioration. When choosing packaging bags, it is important to choose materials with good sealing properties, such as plastic and composite materials. Aluminum foil composite bags have excellent oxidation resistance and are suitable for long-term storage of pistachios.

○ Load bearing performance: Pistachio packaging bags need to have a certain load-bearing capacity to prevent damage during transportation and handling. Plastic and composite packaging bags have good load-bearing performance, and suitable thickness and strength materials can be selected according to actual needs.

○ Printing effect: The printing effect of packaging bags directly affects the product image. When choosing, pay attention to the printing adaptability of the material. Both plastic and paper materials can be used for color printing, but there are differences in printing effect and cost. Enterprises can choose suitable materials based on budget and design requirements.

○ Cost: The cost of packaging bags made of different materials varies. When selecting materials, enterprises should fully consider cost factors and choose materials with high cost-effectiveness while meeting product quality and market demand.

About Us

Fujin New Materials, After Several Years Of Development, Has Developed Into A Packaging Enterprise With A Certain Scale. Our Company Integrates R & D, Design, Printing, Bag Making, Testing And After-Sales Service Into A Comprehensive Printing Company. Our Company Is Specialized In Producing Vacuum Food Bag, Aluminum Foil Bag, Opp Bags, Pe Bags, Recyclable Coffee Bag, Kraft Paper Ziplock Bags, Snacks Packaging Pouches, Stand Up Ziplock Bags, Pet Food Bag, Etc.